Sep, 16 2025

Sep, 16 2025

You clicked to get a straight answer: what do people actually call small-scale manufacturing, and which term should you use? Here’s the short version-there isn’t just one name. The label changes with audience, location, and production style. In this guide, I’ll decode the common terms, show how governments define size, give you rules of thumb for when to use each label, and walk through real examples so you can describe your setup with confidence and pass compliance checks without drama. If you’re pitching to investors, filling out permits, or writing your website, this will save you time and help you sound credible.

TL;DR: The quick answer and when to use each term

Different people use different labels for the same idea. Use the term that matches your audience and how you actually produce. Here are the names you’ll hear most:

- small scale manufacturing - Plain, widely understood. Safe for general use online, proposals, and conversations.

- Micro manufacturing - Very small footprint, often <10 staff; fits makers, labs, 3D print farms, tiny assembly shops.

- Small‑batch manufacturing - Focus on short runs, frequent changeovers; great for food, cosmetics, apparel, ceramics, electronics prototypes.

- Cottage industry - Home‑based or artisan, family‑run. Think candles, soaps, baked goods, textiles, woodworking.

- Job shop - Custom, make‑to‑order machining, fabrication, and assembly; low volume, high mix.

- Light manufacturing - Clean, low‑impact processes. Beware: it refers to process intensity, not company size.

- SME/MSME (policy term) - “Small and Medium Enterprise” or “Micro, Small and Medium Enterprise.” Useful for grants, tax credits, and tenders; size thresholds are defined by governments.

Rules of thumb based on audience:

- Talking to customers: “Small‑batch” or “artisan” if quality and craft matter. “Job shop” if you do custom machining/fabrication.

- Talking to government/banks: “SME” or “MSME” (policy language) plus headcount/turnover numbers.

- Talking to engineers/startups: “Micro manufacturing” or “micro‑factory” if you use modular/3D‑printed/tooling‑lite methods.

- Permits and planning: “Light industrial/light manufacturing” focuses on emissions/noise/traffic, not size.

How governments classify you (2025 snapshot for credibility):

- European Union/UK SME reference: Micro <10 staff; Small <50; Medium <250, with turnover or balance‑sheet limits (European Commission SME definition; the UK commonly aligns in practice).

- United States: SBA size standards vary by NAICS; many manufacturing categories set “small” at <500 employees (check your NAICS code).

- India: MSME (2020 notification, still current): Micro ≤ ₹1 crore investment and ≤ ₹5 crore turnover; Small ≤ ₹10 crore and ≤ ₹50 crore turnover; Medium ≤ ₹50 crore and ≤ ₹250 crore turnover.

How to choose the right label (and prove it): a simple step‑by‑step

Here’s a fast way to pick the most accurate term and back it up with facts when someone asks.

-

Start with your audience. Who needs to understand you?

- Customers: Use “small‑batch,” “artisan,” or “custom job shop.”

- Regulators/planners: Use “light manufacturing,” plus your specific process (e.g., food prep, electronics assembly).

- Banks, grant bodies: Use “SME/MSME,” then your headcount, turnover, and investment.

- Peers/engineers: “Micro manufacturing,” “micro‑factory,” or “prototype/low‑volume production.”

-

Quantify your scale. Capture a few simple numbers you can share consistently:

- People: Total headcount and number on the shop floor.

- Capacity: Units per month for your top SKU, or hours of machine time per week.

- Batch size: Typical run length before changeover.

- Footprint: Square metres/feet and any home‑based constraints.

- Capex: Rough investment in equipment.

-

Map your production mode. This is the key to picking a term:

- Make‑to‑order, high‑mix, low‑volume → “Job shop.”

- Repeat short runs, frequent changeovers → “Small‑batch.”

- Home/atelier, handcrafted → “Cottage industry/artisan.”

- Tooling‑lite, digital fabrication (CNC/3D print) → “Micro manufacturing/micro‑factory.”

- Clean, low‑noise processes → “Light manufacturing” (for planning/permits).

-

Check policy fit. If you need grants or tax benefits, compare your numbers to official thresholds:

- EU/UK: Staff bands (micro/small/medium) and turnover/balance sheet limits.

- US: SBA size standards for your NAICS code.

- India: MSME investment/turnover thresholds.

-

Align with your brand. If you sell premium craft goods, “cottage/artisan” helps. If you sell to engineers, “small‑batch micro‑factory” sounds modern and precise.

-

Write a one‑line descriptor. Fill this in and reuse it on your site, LinkedIn, and proposals:

“We’re a [term from above] focused on [product/process], producing [units per period] with [headcount/machinery], operating under [relevant classification] for compliance.”

Example: “We’re a small‑batch micro‑factory producing 2,000 PCB assemblies per month with 6 staff and two pick‑and‑place lines; we qualify as a micro‑enterprise under EU SME bands.”

Quick decision tree you can keep in your head:

- Home‑based + handcrafted → Say “cottage industry” or “artisan.”

- Custom one‑offs to short runs, lots of setups → Say “job shop.”

- Repeat short runs, branded consumer goods → Say “small‑batch manufacturer.”

- Compact, digital, modular equipment → Say “micro manufacturing” or “micro‑factory.”

- Permitting form asks process intensity → Tick “light manufacturing.”

Real‑world examples across sectors (with useful numbers)

The labels make more sense with concrete scenarios. Here are five typical formats and what their week looks like.

1) Artisan food producer (small‑batch / cottage industry)

- Product: Hot sauce, chutneys, or nut butters.

- Scale: 800-2,500 jars per month; runs of 100-300 jars per batch.

- People and kit: 2-5 people; 30-50L kettles, induction hobs, bottle capper, labeller.

- Where: Registered kitchen or shared commercial unit; local council approval (UK), local health department (US).

- What to call it: “Small‑batch food manufacturer.” If you make at home under exemptions, “cottage food” applies in many US states; in the UK, you still register with the local authority.

- Margins and gotchas: Aim for 60%+ gross margin. Watch pH/aw controls, allergen labelling, and shelf‑life testing.

2) Cut‑and‑sew studio (small‑batch)

- Product: Apparel capsules, soft goods, aprons, tote bags.

- Scale: 50-500 units per SKU per month; frequent changeovers.

- People and kit: 3-10 machinists; lockstitch/overlock machines, cutting table, pattern software.

- Where: Light industrial unit; no heavy emissions.

- What to call it: “Small‑batch apparel manufacturer” or “atelier” if premium.

- Margins and gotchas: Set minimum order quantities (MOQs) based on changeover time. Pre‑approve samples to lower rework.

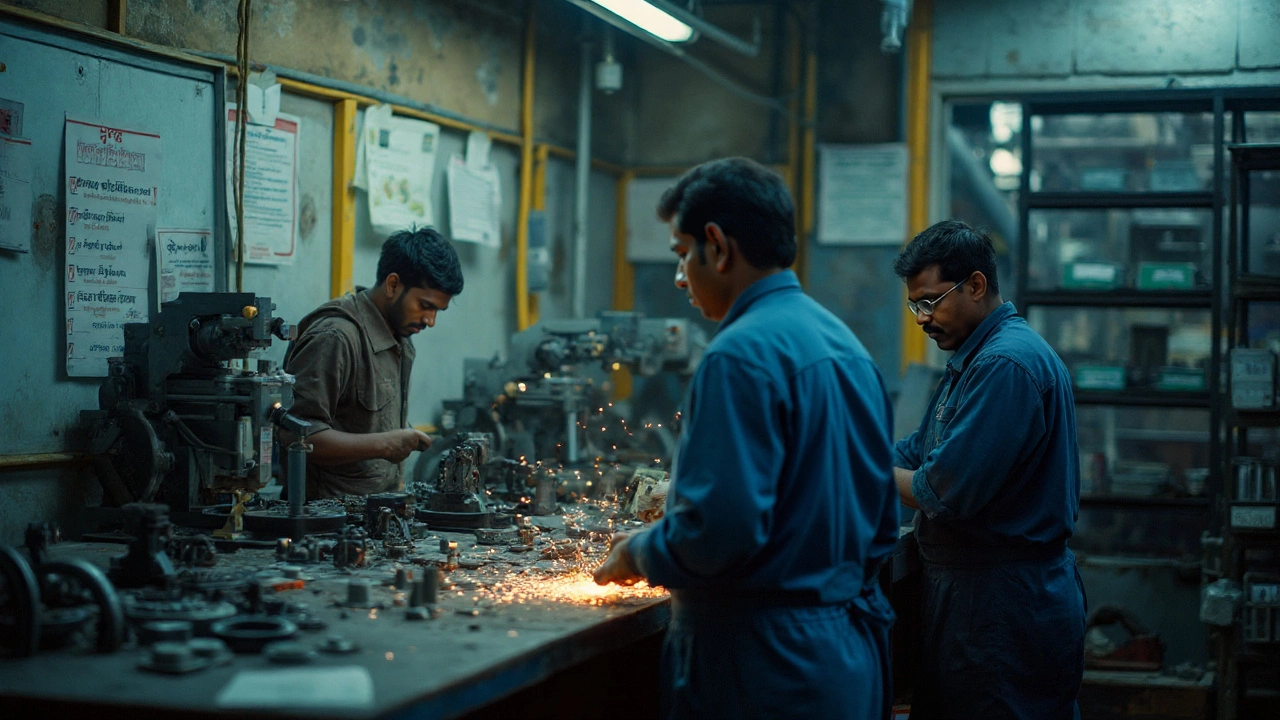

3) CNC and welding shop (job shop)

- Product: Custom brackets, fixtures, prototypes, one‑off frames.

- Scale: Tens to low hundreds of parts a month; each job unique.

- People and kit: 2-12 technicians; 3‑axis mill, lathe, TIG/MIG welders, bandsaw, surface plate.

- Where: Light industrial; noise and fume controls as required.

- What to call it: “Job shop” or “prototype/low‑volume fabrication.”

- Margins and gotchas: Quote by time and complexity; track setup hours religiously. Keep scrap logs and fixture libraries.

4) Electronics micro‑factory (micro manufacturing)

- Product: PCB assembly for startups, IoT devices, niche controllers.

- Scale: 500-5,000 assemblies per month depending on complexity.

- People and kit: 4-12 staff; benchtop pick‑and‑place, reflow oven, AOI, stencil printer, ESD workstations.

- Where: Clean, light industrial or converted office; minimal noise/odour.

- What to call it: “Micro‑factory” or “micro manufacturing.”

- Margins and gotchas: Control changeovers with feeder carts. Lock BOMs early. For CE/UKCA/FCC, clarify responsibilities if you’re only assembling.

5) Ceramics studio (cottage / small‑batch)

- Product: Tableware and tiles.

- Scale: Dozens to a few hundred pieces per month; firing bottlenecks.

- People and kit: 1-6 artisans; kilns, wheels, slab rollers, glazing area.

- Where: Studio or home outbuilding; ventilation and kiln clearances matter.

- What to call it: “Cottage ceramics studio” or “small‑batch ceramics manufacturer.”

- Margins and gotchas: Fire to a schedule and standardise glazes. Track energy consumption per firing.

Bonus mini‑formats you’ll see everywhere:

- 3D print farm → Micro manufacturing / digital fabrication.

- Woodworking shop → Job shop (custom) or small‑batch (repeat SKUs).

- Soap/cosmetics lab → Small‑batch; GMP‑lite controls help.

- Bike frame builder → Cottage/artisan or job shop, depending on customisation.

Useful scale signals to sanity‑check your label:

- If you run 80% custom work with setups every day → You’re a job shop.

- If 70% of your volume is repeat SKUs in runs <1,000 units → You’re small‑batch.

- If you operate in <200 m² with modular, digital kit → Micro manufacturing fits.

- If your process is quiet/clean and neighbours don’t complain → You’re light manufacturing for planning.

Terminology cheat sheet, checklists, and practical rules

Cheat sheet: term → when to use it

- Small‑scale manufacturing → Plain‑English umbrella, safe almost everywhere.

- Micro manufacturing → Tiny footprint/headcount, digital or modular kit.

- Small‑batch manufacturing → Short runs; good for consumer goods and DTC brands.

- Cottage industry → Home‑based, artisanal, handcrafted.

- Job shop → Custom, make‑to‑order machining/fabrication.

- Light manufacturing → Clean, low‑impact processes (permits/planning).

- SME/MSME → Policy classification for finance and incentives.

Compliance checklist (start here, then localise)

- Premises: Check local planning/use class. In England/Wales, many clean processes fall under Use Class E(g)(iii) “light industrial.”

- Safety: Do a risk assessment. Follow HSE (UK), OSHA (US) or equivalent. Guard moving parts; manage dust, fumes, and noise.

- Food/cosmetics: Register with your local authority (UK) or health department (US). For EU/UK, follow hygiene regs and cosmetic product safety rules; in the US, review FDA frameworks.

- Electrical/electronics: For placing products on the market, confirm CE/UKCA/FCC compliance scope. If you’re only assembling to a client’s spec, document responsibility.

- Chemicals: Check REACH/CLP (EU/UK) or SDS/OSHA HazCom (US). Store, label, and dispose properly.

- Fire: Extinguishers matched to risks, clear egress, hot‑work permits where needed.

- Insurance: Public/general liability, product liability, employer’s liability if you have staff.

- Waste: Licensed disposal for solvents, oils, electronics, and sharps if applicable.

Documentation that pays for itself

- Spec sheets and drawings with revision control.

- Standard operating procedures (SOPs) for the top five processes.

- Device history records or batch records (what materials, who did what, when).

- Calibration logs for scales, thermometers, torque tools.

- Corrective action log to stop repeat mistakes.

Quick finance/ops formulas you’ll actually use

- Minimum viable batch size (MVB): MVB ≈ Setup time × Hourly fully‑loaded rate ÷ Contribution margin per unit.

- Quoted lead time: Lead time ≈ (Queue + Setup + Run + Inspection + Ship). Post the sum, not just run time.

- Target gross margin: B2C 60-70%; B2B 35-50%. Adjust if you carry tooling or warranty risk.

- Changeover tax: Every changeover you don’t standardise costs 30-90 min. Reduce by kitting, colour‑coding, and pre‑staging.

When labels affect money

- Grants/credits: SME/MSME status can unlock R&D tax relief, capital grants, and export support. Check your headcount/turnover against official thresholds.

- Customs and trade: You may need EORI (EU/UK) or importer IDs; the label on your customs paperwork is your product HS code plus your legal entity, not “cottage” or “small‑batch.”

- Certification: ISO 9001 can help you win B2B work even at tiny scale. Start with a lean QMS and grow into it.

Common pitfalls and how to avoid them

- Calling yourself “light manufacturing” to sound small when your process is dusty/noisy-planning officers care about impact, not your vibe.

- Using “cottage” while selling nationally without proper food/cosmetic registration-authorities will still expect compliance.

- Underquoting by ignoring setup time-bake setups into every price or set MOQs.

- Buying big‑iron equipment before mastering changeovers-start with flexible kit and standard work.

- Skipping documentation because “we’re small”-that’s how you lose traceability and customers.

FAQ and next steps

Is “small‑scale manufacturing” the same as “light manufacturing”?

No. Small‑scale refers to company size and volume. Light manufacturing refers to the impact of your process (cleanliness, noise, emissions). A tiny welding shop might not be “light,” while a 40‑person electronics assembler usually is.

What’s the difference between “micro manufacturing” and a “micro‑factory”?

Micro manufacturing is the concept (very small scale). A micro‑factory is the physical setup-compact, modular lines with flexible tooling, often using digital fabrication. Use either, but “micro‑factory” paints a clearer picture for engineers and partners.

Is a job shop always small?

Plenty of job shops are small, but the model scales. The defining feature is high mix/low volume and make‑to‑order, not headcount.

Can cottage industry products be sold in shops or online?

Yes, as long as you follow the same product safety and labelling rules as larger firms. “Cottage” describes how you make it, not an exemption from law.

Do I need ISO 9001 to sell B2B?

Not always. Some customers require it. Many small shops win work with a lean quality system (document control, calibration, batch records) and add ISO later.

Which term should I put on my website?

Use the term your buyers search for. Consumer brands: “small‑batch.” Engineering clients: “job shop,” “prototype and low‑volume,” or “micro‑factory.” For your About page footer, add SME/MSME details if you apply for grants.

What should I say on planning/permit forms?

Describe the process (e.g., “electronics assembly, light industrial”) and list equipment, hours, emissions, and deliveries. Avoid vague labels-officers need impact details.

When do I stop calling it small‑scale?

When your volume, headcount, and footprint clearly exceed micro/small bands in your region or when you move to long‑run production. If you’re running tens of thousands of units per SKU with long campaigns, call it “mid‑scale” or just “manufacturer.”

Is “artisanal” a legal term?

No, it’s marketing language. If you use it, still comply with product safety, labelling, and traceability rules.

Can I be small‑scale and contract out?

Yes. Many small businesses design and finish in‑house and subcontract machining, PCB fab, or packaging. Be clear on who owns compliance and quality at each step.

Next steps: pick the right term and make it stick

- Choose one primary label for customers (“small‑batch,” “job shop,” “micro‑factory”) and one policy label (SME/MSME).

- Write your one‑line descriptor with numbers (units/month, headcount, premises type).

- Update your website, LinkedIn, and proposals to use the same phrase-consistency builds trust.

- Check your local planning/use class and register where required (food, cosmetics, etc.).

- Create five SOPs for your most common processes and a simple batch record-tiny effort, big payoff.

- Set pricing that covers setup time; add a minimum order or setup charge.

Troubleshooting different scenarios

- If a buyer says “You’re too small for us” → Lead with quality controls, on‑time metrics, and certifications; offer pilot runs with clear acceptance criteria.

- If a planner flags your site → Provide a process description, equipment list, hours, noise/fume data, and mitigation steps. Emphasise “light industrial” if accurate.

- If margins are thin → Increase batch sizes to your MVB, standardise changeovers, and raise prices on low‑run SKUs.

- If you’re drowning in custom work → Split into standard SKUs (small‑batch) and custom jobs (job shop) with separate pricing and lead times.

- If you want grant support → Document SME/MSME status with headcount and turnover; prepare a lean project plan and budget.

If all you needed was the name, you’ve got it. If you’re shaping a brand, applying for permits, or building a reliable operation at small scale, the labels here will help you pick the right words-and back them up with the numbers that matter.